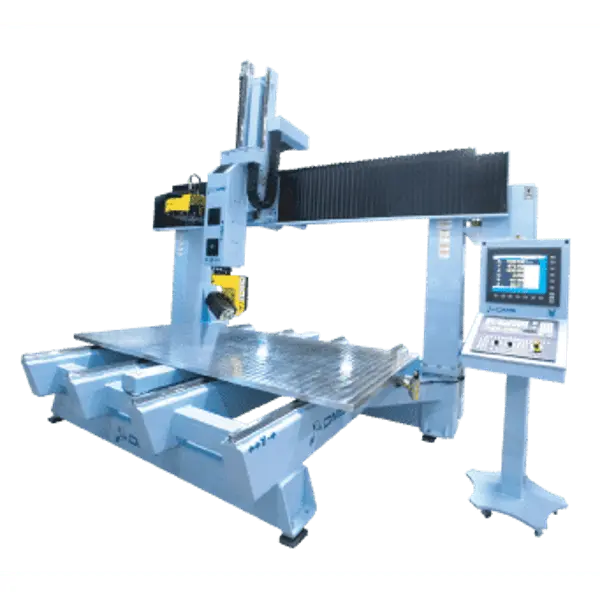

BASE MODEL MACHINE

This 5-Axis long bridge twin moving table machine features two 5 foot/1.5 meter by 5 foot/1.5 meter aluminum tables machined flat and configured with 3/8 inserts on 12 inch/.30 meter centers. This machine is capable of rapid feed rates of 1800 inches/46 meters per minute and rotational speeds of 8000 degrees per minute.

This machine is constructed of a rigid, fabricated steel base, utilizing heavy gauge steel tube and plate weldment construction throughout. All structural members are stress relieved for maximum stability, and all surfaces that mount precision components are precision ground and/or machined. All linear axes are equipped with profile ways and laser aligned and compensated for positional accuracy.

X-AXIS

X-axis is the bridge axis which is driven by a spinning ball nut and recirculating ball screw assembly spanning the 10 foot/3 meter dimension from left-to-right across the workspace. Maximum travel is 132 inches and allows for full workspace coverage. (Actual travel may vary based on options selected.)

Y-AXIS Y-axis is the moving table axis which is driven by a spinning ball nut and recirculating ball screw assembly spanning the 5 foot/1.5 meter dimension from front-to-back across the workspace. Maximum travel is 72 inches and allows for full workspace coverage. (Actual travel may vary based on options selected.)

Z-AXIS Z-axis travel is 36 inch/.90 meter and is driven by a recirculating ball screw assembly. Maximum feed rate is 1000 inches/25 meters per minute.

C-AXIS (4th axis) C-axis rotates parallel to the table utilizing a Cycloidal gear reducer with a travel range of +/- 363 degrees.

B-AXIS (5th axis) B-axis rotates perpendicular to the table utilizing a Cycloidal gear reducer with a travel range of +/- 115 degrees.

CONTROL SYSTEM

Fagor 8055i Power with 512MB of compact flash memory, 10.4" high resolution color LCD monitor, USB and serial ports, 3D solid graphics, TCP/IP Ethernet & loaded basic functions, including Retrace, Telediagnostics & TCP with a complete set of Fagor manuals on CD. Fagor AC digital Sercos drives with a closed loop AC brushless servo motors on all axis and absolute encoders on all linear Axes. (Includes transformer)

Control: Pulse Generator This hand held unit provides manual axes positioning in the Jog Mode and Remote Feedrate Override in the Execute Mode. When connected to the Fagor Model 8055 CNC control it offers basic point to point toolpath digitizing. The device includes a rotary handwheel pulse generator, axis select switch, resolution selector switch, keypad Teach-In digitizing functions, 3 position enable push button with double channel safety circuit and an Emergency Stop pushbutton. The unit features a 3.5 meter cable for connection to the Fagor CNC operator control panel.

Performance: A/C 2000 BTU air conditioner with evaporation tray for main electrical cabinet. Cabinet is sealed and dust tight. This is required for composite materials, and recommended for wood.

Performance: Software Autodesk PowerMill Standard bundle includes 2D Milling, 3D milling, 3+2 positional 5-axis milling, a 3D Solid simulation model, and post processor for your DMS CNC Router. Autodesk PowerMill is the market leader in expert high-efficiency 3D and 5-axis positional machining. DMS’ Autodesk PowerMill Standard bundle allows you to utilize the industry’s most effective CAM tool out of the box while being supported by the best technical team in the industry. Includes PowerMill Standard online training course Includes PowerMill Premium classroom training, 4-days at DMS factory in Colorado Springs, is provided quarterly. Travel expenses are not included. Your initial 12-month subscription is our gift to you with this DMS machine purchase.

Spindle ES950 6.2Hp/4.6kW 230/380V ISO30 short nose HSD ATC spindle, max speed 24,000 rpm, S1 continuous 3.8kW/5.1Hp, spindle is air cooled. A frequency inverter with electronic braking is used to program the spindle speed from 2,000 to 20,000 rpm. Collet range is up to 3/4" with ER 32 collets and 1" with ER 40 collets.

Spindle: ATC A 12 position traveling carousel tool magazine mounted on the backbone. The carousel is servo-driven and pneumatically actuated into position by the controller for automatic tool changes. Note: Full bridge bellows option not available with this tool changer. Maximum tool size: 4.00" diameter x 4.50" length and 1.00" diameter x 8.00" length from spindle face to tool tip. Tool diameter and length may be limited by the size of adjacent tools on carousel.

Performance: Tool Height DMS tool height sensor used for measuring the tool length for each tool and loading the value automatically in the tool table. Note: May reduce tool pockets by (1) one.

Performance: Table (2) 2" automatic solenoid operated vacuum valve for parts hold down, includes a vacuum hose connection. The valve is integrated with the controls and is M-code activated from the console.

TOTAL: $185,000.00

We use cookies to improve your experience. Privacy Policy.